ESEM Science and Technology

Commercial ESEM

Background

In about the second half of 1985, a venture capital

company, ElectroScan Corporation, was formed by a group of

people north of Boston USA, in order to commercialize the idea of

introducing gas in the specimen chamber of a scanning electron microscope

(SEM). The first engineering attempt was based on advice and a patent

by

Alan Nelson (US4720633)

, which however

soon failed to produce any image. By November of 1985, the group sought the

assistance by Danilatos in Sydney who already had produced a working prototype with numerous

publications. Under Danilatos guidance, the first image in a gaseous

environment was obtained at the ElectroScan premises within three

days, i.e. on the 5 February 1986. A

new commercial instrument

, the environmental scanning electron microscope or ESEM was thus born,

and within a few years of manufacturing developments it was to be

fully marketed by 1988.

The first imaging was obtained with the use

of correct differential pumping between two thin-wall apertures

as opposed to the stacking of a series of apertures without pumping between

them as per Nelson patent. The latter stack of apertures traps

air over an extended transition region in which the primary electron beam is

catastrophically scattered and lost. A series of apertures like

that may have a better engineering separation of the vacuum region in the

column from the pressurized specimen chamber than a single aperture of the

same diameter. However, such a series of apertures constitutes the

worst approach for a working ESEM at (a) the lowest beam

kV, (b) minimum beam loss and (c) highest gas pressure.

Initial imaging at ElectroScan was based on the use of a

scintillating backscattered electron (BSE) detector but Danilatos insisted also

on the use and development of a new detection principle already pioneered

and practiced on the prototype since 1983. The latter consisted of

the use of the ionization of gas by various signalsas

a detector for those signals. Since the secondary

electron (SE) imaging constituted the

basic mode of detection in most conventional SEMs, the company work

concentrated on making the gaseous secondary electron detector the basis of

the new instrument, for which a new patent

(US4785182) application was lodged.

ElectroScan also designed and built their own

home grown electron optics column that integrated differential

pumping in the objective lens (US4823006). Unfortunately, whilst

differential pumping was very good, the geometry of a flat bottom pole-piece

placed severe limitations on the integration of detectors and specimen

movement. In this respect, the commercial instrument was severely

constrained from reproducing the results already on record by the

Danilatos prototype. The optimal BSE detectors (17) already developed by Danilatos (see

also design shown here ) could not be used on this

commercial ESEM and thus this mode of detection was compromised. The

first offered scintillating BSE detector, or the later use of third party

BSE detectors of an earlier era have resulted in the commercial ESEM

lagging seriously behind the Sydney prototype ESEM ever since.

It has not been appreciated that both BSE and SE modes of detection

are highly relevant in ESEM developments as opposed to the lopsided development

of one only over the other.

Danilatos ceased to be an adviser to ElectroScan in

1993, whilst ElectroScan was bought by Philips shortly afterwards and by

FEI later on. The introduction of the Philips conical objective lens

was a step in the right direction with much potential, but none of the later

developments were done under any instructions or guidance by

Danilatos. The optimal BSE detectors were not incorporated as they could

and should, whilst new issues emerged as described below.

In recent years Danilatos advised LEO (now Zeiss) on ways

to enter the ESEM market with an ESEM of their own make capable of using the

gaseous secondary electron mode in the extended pressure range, together with

optimal BSE detectors. Success in this direction will be measured by

the extent of such implementations.

Users of commercial ESEMs should be aware that

any deviations of performance from the reported results by the Danilatos

prototype ESEM are the responsibility of the corresponding manufacturer and

that such deviations do not represent any inherent weakness of the principles

involved. Through the entire research period, including the times

when Danilatos received financial support from some companies, all

Danilatos works and reports are based on pure science away from any bias

arising from commercial interests or other considerations. These works

have aimed to establish the theoretical and practical physical limits in the

design and construction of an ESEM. Hence the manufacturers should use

such works as a benchmark and the users should satisfy themselves that

their instruments live up to their expectations.

Problems and Solutions

The commercial availability of ESEM has given a

tremendous impetus in many fields of applications and for the first time the

international scientific community have enjoyed possibilities un-thought of

previously with the vacuum SEM. However, when some commercial design

aspect is not what it should be, it may not be easy to rectify immediately, as

the production of a particular model results in the installation of a

significant number of units in the market. The only or best reaction then

would be for clients provide a feedback somehow to the manufacturer in the hope

that the identified problem will be rectified with the next generation of

microscopes. Some users have expressed certain concerns on instrument

performance and Danilatos occasionally offered some assistance when the users

sought it. Some key problems that need fixing are included herewith:

Electron beam transfer

At the University of Technology (UTS) using a Philips

XL30 ESEM, it was found that imaging became impractical or impossible

as the pressure reached 1000 Pa and acceptable work was mostly

performed with the aid of a cooling stage to lower the saturation water vapor

pressure close to 600 Pa and/or with the use of the highest beam kV. Upon

visual examination of the aperture bullet system, it was thought that the

geometry was in serious deviation from the optimum design and a

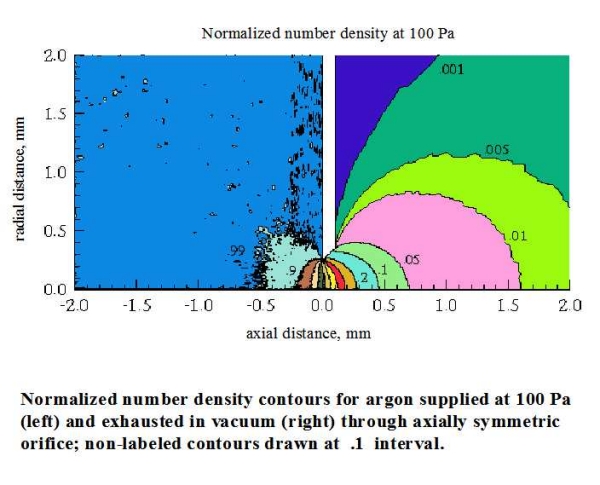

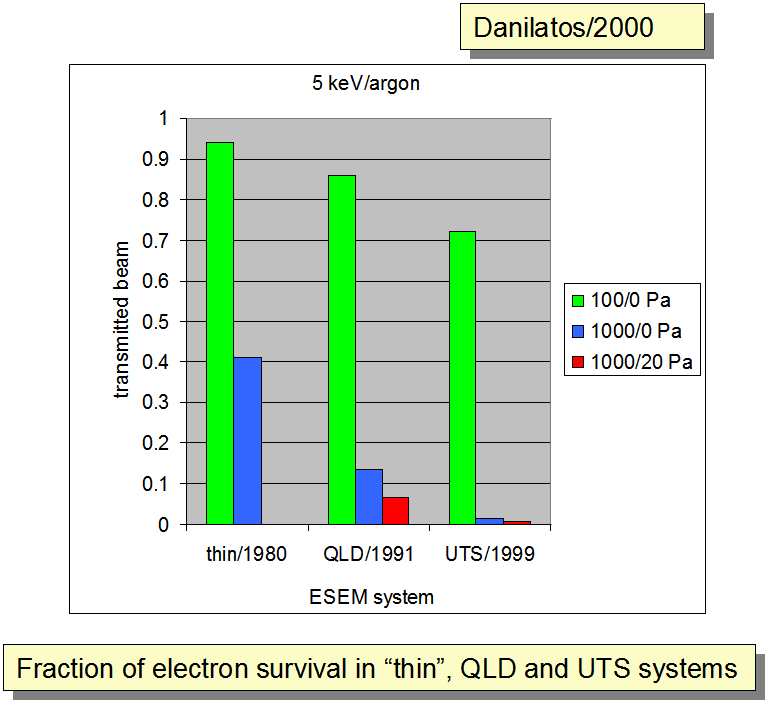

computational determination of the gas flow was undertaken. In Fig. 1 the

pressure (or density) gradients are shown along the axis of the bullet

system: A 0.5 mm bottom pressure limiting aperture (PLA1) is

shown on the left side, with the vacuum of the column on the right side

separated by the second (upper) PLA2. Significant gas layers develop

throughout the bullet system between the two apertures, with the highest values

of gas density inside and around the vicinity of the bottom PLA1 which

is also shown at an enlarged view in Fig. 2.

|

.jpg)

Fig. 1 Gas density gradients inside the "bullet" of the

UTS ESEM |

.jpg)

Fig. 2 Gas density gradients (enlarged view) through the pressure

limiting aperture (PLA) of the UTS (previous) "bullet". On the left

side (in red) is the specimen chamber at 10 mbar pressure. The

electron beam has to overcome the stagnating gas inside the PLA cylinder

after already having undergone significant losses in the intermediate

space between the two PLAs. |

|

.jpg)

Fig. 3 Gas density gradients inside the QLD ESEM. There is

less overall stagnating gas than the UTS bullet. |

Fig. 4 The pressure gradients with a "thin" PLA are

sharpest and the electron beam losses are

the lowest possible for optimum beam

transfer: See latest paper or (57)

|

The same work was repeated on an early ElectroScan

U3 ESEM model used by the University of Queensland (QLD) and the

corresponding gas density in the bullet is shown in Fig. 3.

Last, the gas flow density was computed for a single thin

aperture having maximum conductance downstream of the flow (free

space). The density contours are shown in Fig. 4. The latter is

taken from a rigorous investigation of the gas flow in the

complete range of pressures up to atmospheric pressure for different gases

including water vapor. In practice, this

situation can be closely achieved with proper care of the aperture construction (e.g. conical

shape) , mounting and configuration, together

with various detectors

.

An integration of the gas density along the axis between

the apertures yields the total mass thickness which the electron beam has to

overcome before it enters the specimen chamber (on the left of PLA1). The

amount of total electron beam loss along the axis in this region has been

computed for a series of conditions and

the results have been

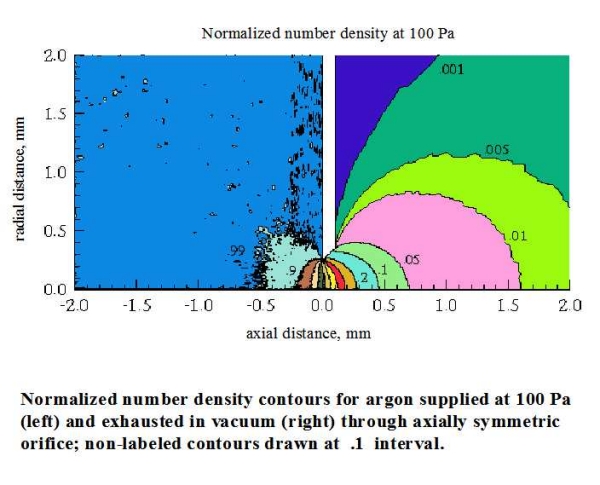

presented in detail twice in (54) and (56) . These results are summarized in

Fig. 5 showing the total electron beam loss for the three cases of

instrument design mentioned above. It is immediately seen that the older

commercial model performs better than the newer, but both perform worse

than the physical limit obtained with a thin aperture, as used on the

prototype ESEM.

Fig. 5 Comparative presentation of the

electron beam losses for the three cases of PLAs presented in the previous

figures

The results from the work on thin apertures have been

used to establish the electron beam transmission (or loss) in the complete

accelerating voltage range, gas pressure range and working distance range

for different gases. Whilst already published works can lead to these

results, much work still remains unpublished in a comprehensive

form, which however can be available to interested

parties, e.g. manufacturers [See latest paper or (57) ]. By such means we have

established the physical limits which every ESEM should tend to approach, i.e.

the closer to this limit the better. In fact, the Prototype ESEM has been

shown to operate practically at this limit, which has resulted

in the production of the best raw images emanating from the best physics

and not from any image processing technique. One would then expect to have

obtained even better results by modern computer image processing more than 20

years after the pioneering work took place. Unfortunately, this is not

born out by the subsequent commercial instruments like the ones presented

herewith [as it should be stressed again that the later commercial models

perform worse than

the earlier

, and all of them worse than

the original prototype]. Clearly, the thick wall PLA1 (as in Figs. 1,

2 and 3) has a similar effect as the series of apertures used in the

Alan

Nelson (US4720633) patent. It is not clear if this has

been a deliberate engineering attempt to decrease the gas

leak through the thick aperture (at the expense, however, of electron beam

transmittance), or a persistent engineering oversight, or some other

reason. In any case, it seems like

another commercial behavior operating against proven science and

practice, but with some very disappointing results for ESEM.

The consequence of using a cylindrical instead of a thin

wall PLA1 has far more destructive effects in addition to the beam

loss. The cylindrical geometry has a large inside surface which is

prone to quick contamination. Any debris in contact with the surface gets

irradiated and firmly stuck against the surface. At low pressure, or if the user

wishes to revert to vacuum operation, any contamination inside the PLAs will

create serious astigmatism on account of charging. The charging can be so

great by the incident beam that even at increased pressure the gaseous

ionization may not suffice to balance off the amount of charging and hence

imaging becomes problematic and a general malady for the instrument over

all. Furthermore, the position and shape of PLA2 together with the

overall "bullet" (apertures-evacuation assembly) design are critical to prevent

contamination of the upper column, which can drastically reduce the

lifetime of the electron gun and affect normal/efficient electron probe

formation. Users who find it difficult to focus and get clear images

or experience short gun lifetime should become aware of the

causes of their difficulties. Manufacturers should address these problems

both on new instruments and on the ones already in place out on the

market. Solutions do exist for those who wish to have them.

Restoration of the field of view at low

magnifications

Another tested improvement (also solution to

above problems) regards the " field of view" which has been

compromised for a long time in ESEM including the early prototype: The

pair of apertures used creates a "tunnel" vision at low magnifications, which

inhibits, or makes difficult the observation of a large area before the user

zooms-in over a small feature of interest. The practice of increasing the

diameter of PLA1, as a means to increase the field of

view, quickly reduces the working pressure range on account of increased

gas flow and increased gas density gradients in the bullet. As a result,

either very high beam accelerating voltage must be used at low pressure or

imaging is impossible at elevated pressure. This problem has been overcome

with a recent

patent (US6809322) that allows the use

of a much smaller (and thinner) PLA1 with simultaneous much greater

field of view than hitherto used. This at the same

time increases the useful pressure range and decreases the accelerating

voltage needed for the beam. The practical

consequences of such means are enormous: Better resolution on

"soft" specimens with much less beam damage at higher

magnifications/resolutions. Furthermore, smaller PLA (without compromising

the wide field of view) means less probability to contaminate the upper

column, better imaging, long electron gun life, etc...

Accessories, in situ applications and true TV scanning

rate

ElectroScan also developed and sold two

important accessories for the ESEM, namely, a hot stage with which specimens

could be heated at more than 1000 degrees C, and a cooling stage using the

Peltier principle. The hot stage took a big proportion of the R&D

effort, presumably prompted by demand in that area of

application. The cooling stage was mainly prompted by the difficulty

experienced by the engineers to operate the ESEM at room temperature and

high pressure. However, there is also a third ancillary device in

great need, namely, a microinjector device that allows deposition of

liquid droplets of the smallest possible size in a controlled stop/start

manner. A commercial version of such a device became available by the use

of a capillary needle connected to a syringe at ambient pressure outside the

microscope. However, this approach invariably resulted in the

flooding of the specimen stage with water, since the flow could not be stopped

or controlled in any way: By pulling the syringe plug back, the back

pressure at the plug remains at saturation vapor pressure at

ambient temperature, whilst the pressure at the specimen was at saturation

pressure at the cooling stage temperature which was always lower than at room

temperature. If the pressure at the plug is greater than the pressure at

the tip of capillary needle (near the specimen), it is impossible to stop the

flow of water from the syringe to the specimen. Clearly, that approach was

bound to fail, because the water could not be sucked back and could not be

stopped or controlled. Because of this phenomenon, a solution to

the problem was found and published by

Danilatos

and Brancik

(27) a long time earlier: The syringe

was connected to a pipe loop that opens back out to room

(ambient) pressure. Water flowing in the pipe loop supplies on

its way the back of the capillary needle, or water can be freely sucked

back in the syringe emptying the back of the capillary needle. In this

manner, water could be freely pushed back-and-forth between the

syringe and the back of the capillary needle, hence a controlled start-stop

situation could be easily achieved. Such a microinjector was successfully

used for a long time and many hours of video recordings at true TV

scanning rates were obtained during the years 1980-1985. Some still images from those

recordings have been published . Also, some excerpt

recordings were copied to VHS cassettes and retained by

ElectroScan. They were shown at the Albuquerque EMSA Meeting in

1986, as they were also used to promote the ESEM at the outset of its

commercial development. To date, no such video recordings at true TV scanning

rates have ever been shown from any commercial ESEM .

The necessity to use a cooling device on a regular basis

is disappointing, because it is very restrictive as to the ease and range

of applications possible in the commercial ESEM. Having

to control the temperature at a low point prior to observations and

imaging in the ESEM is just another unnecessary complication, even detrimental

to many applications. For example, biological studies of fresh and

living specimens can yield problematic results due to the cooling

device alone. The cooling device should only be used in extreme

situations, whilst for routine operation the ESEM should be usable at room

temperature without further ado.

Backscattered versus secondary electron

imaging

As pointed out before, the use of third party scintillating BSE detectors is most unfortunate, since those have been superseded by

specially designed and devoted ESEM

detectors since 1979. Third party detectors, in general, are

suitable for SEM but not for ESEM, because they cannot fulfill the

stringent requirements of the latter. The manufacturer should have

developed and equipped every commercial ESEM with indigenous (own or homegrown)

design BSE detectors along with the SE gaseous detector. The BSE

certainly should not be offered as an "option" of extraneous detectors of

dubious performance for ESEM. This is an additional reason why

the commercial ESEM has not duplicated, let alone surpassed,

many of the

results obtained by the first laboratory prototype ESEM. There has been

a long and vigorous discussion on the contrast and resolution obtained by BSE

and SE signals and related detectors throughout the 1970s and afterwards.

The best conclusion is that these modes of detection complement rather compete

against each other. Very high resolutions have been demonstrated also with

BSE detectors. Certain misunderstandings have been exploited by

manufacturing expediency in promoting only one mode, as it has happened with the

commercial ESEM. Since patents were owned only on the gaseous SE

detection and not on BSE mode, the manufacturer identified the SE detector

with the ESEM technology in general, and a generation of users have fallen

victim of this misunderstanding too. Good BSE detectors are, in effect,

absent throughout the hitherto existence of commercial ESEM. A

significant percentage of applications would have been far better

implemented in the BSE mode, whilst the lone SE mode has led many users to

erroneous conclusions about the true capability of ESEM. Actually,

the contrast and resolution in ESEM is not limited by either of those modes of

detection in most applications of untreated specimens, but the electron beam

radiation effects often become the limiting factor.

The development of a "helix detector" [also mirrored here]] in a research institute is highly

commendable. Actually, this and scores of other potential developments and

improvements have been envisaged in the "

Theory of the Gaseous

Detection Device " or (36 ) and elsewhere. Many

other research institutes should follow this example. Manufacturers should

also take up specialized developments such as this but not before

the commercial instruments have overcome their existing

fundamental problems and limitations. The "helix" detector certainly does not solve any

of the problems and limitations outlined herewith, and

statements like "However, until the development of the Helix detector, ESEM could not be applied

at the very highest SEM magnifications that are essential for

nanotechnology" are mere misrepresentations of the basic ESEM capabilities in

a proper design. A specialized detector development should not

be given precedence over eliminating other existing basic flaws, the cart

should not be placed before the horse and ESEM should not be

downgraded to operating only at low vacuum. The manufacturers need better direction on

the grounds of a comprehensive understanding of ESEM instead of pursuing

haphazardly a few developments here and there. This brings

us to face the cause of many problems closely: The

self-portrayed "road mappers (on page

10)" of ESEM have not yet

produced a machine to its full potential. More work is needed

to extricate right from wrong.

The basic gaseous

detection device followed by the many modifications as described in

the

Theory of the Gaseous

Detection Device can serve the ESEM for many generations of commercial models to

come, whilst we are not short of novel

detection ideas if the manufacurers were willing to expand even

more.

Resolution of ESEM, radiation effects and instrument

sensitivity

It has been shown that the resolving power of

an ESEM is determined by the electron probe diameter in the same manner as

with a SEM.

Test specimens of gold particles on

carbon can be equally resolved by both instruments

.

Manufacturers compete in the "battle to resolve the Angstrom" and the "nano-"

has become the latest catchword to impress the world with various

"nano-technologies". However, the physics of electron beam-specimen

interactions has not changed an iota no matter how smart an instrument

claims to be. The actual resolution may be spoiled in most applications by

the very radiation effects that accompany the highest magnification

available. For example, if we look at

Figs. 100 and 101 of

Foundations... the edge definition of an ordinary specimen at

moderate magnifications appears blurred following irradiation. The

unaware user would in vain try to sharpen the focus in this case, or may

think the instrument is faulty. This and other types

of irradiation effects have been reported not only with ESEM but also with

SEM. However, ESEM is more demanding in this area because it claims the

privilege to look at natural specimens. Apparently, blasting of a

wetting specimen by the electron beam should not usually be the case

of study (e.g. see "Video Tour EVOŽ Tour 4 of 5" on coffee grain, which is also directly

mirrored here). When one often or easily

sees "bubbling" on the image, one can suspect that either

the instrument or the operator is not performing well (i.e.

optimally). Specimens should be kept as unspoiled as possible. The

only way to achieve this is by the use of the absolute minimum

radiation dosage at the maximum magnification. Actually, a glance in

various journals immediately reveals that the vast majority of applications have not been done or have not

demanded the use of the ultimate resolving power of the instrument in

use. Therefore, it is imperative that the "sensitivity" of microscopes

rather is of prime consideration and should not be compromised

or overlooked by the manufacturers in their

planning to improve their instruments. An optimum beam

transfer [see latest paper

or (57 )] together with the supply

of the most sensitive detectors requiring minimum electron beam intensity

and accelerating voltage are the prime factors that have brought

radiation

effects under control at the minimum possible physical

limit. This is an aspect of paramount importance in the practice of this

technology, an aspect not to be overlooked at all times.

Specimen transfer and environmental

control

Another flaw that has plagued the commercial

instruments is the problematic control of relative humidity, of wetting and

drying a specimen in a controlled way. There are a number of publications

from the use of commercial instruments that bear evidence of this limitation, of

which every user must be aware. This has been caused by the lack of a

specimen exchange chamber (airlock). The entire specimen chamber of

commercial ESEM is evacuated each time a specimen is changed and it

is practically impossible to remove the ambient

gas without initially lowering the relative humidity well below the

100% level. Some users have devised a routine of cycling the pumping a

number of times before they can reach a saturation (wet) state in the

chamber, but this imposes severe limitations on many applications,

especially in the examination of fresh and live biological samples

where relative humidity matters. This is time consuming and detrimental

both to the application and to the instrument in which huge pressure

differentials on the PLA (and gas flow) increases the chances of

contamination. The prototype ESEM has overcome these limitations right

from the outset because the modified JEOL JSM-2 SEM is equipped with

an airlock, which is appropriately connected to the pumping system of the

ESEM (see OPERATION AND APPLICATIONS as well as other

numerous publications by Danilatos). Specimens are inserted in the

specimen chamber within a minute and never have to undergo any drying condition

whatsoever. The airlock contains a quantity of water which allows

lowering of the ambient pressure monotonically to the 100% (wet) condition, and

then the specimen is inserted in the main chamber which is continuously

maintained at 100% relative humidity without interruption with each specimen

change. This is speedy and safe both for the specimen and the overall

operation of the instrument, as is outlined in relevant publications ( 28 ). Incorporation of a water

reservoir inside the commercial chamber would again limit the scope of

applications and relative humidity control, hence the inclusion of an airlock

properly integrated with the pumping manifold is the best solution to an

existing market problem. Perhaps manufacturing expediency, once more,

determined the elimination of a classical airlock from routine instruments as

those instruments were addressing the needs of the bigger industrial market

applications (presumably) than lesser market of biological

applications. The validity of such an argument may be questioned, as it

may also be questioned why an instrument has to have only one or the other

specimen transfer mechanism and not both. The whole problem is reduced to

a problem of engineering efficacy. It is finally reduced to a question of

whether the engineering management is in tune with and qualified to address

these problems.

Conclusion

It is disappointing that good workers, while they

genuinely strive to understand the new physics of ESEM, accept their

commercial instruments uncritically. Indeed, it is strange that some

users, especially of latest commercial ESEM, seem oblivious to the

severe limitations of their instruments and have actually become

subservient to them (after all, they have to justify their budget

expenditure). They wouldn't even think of modifying their instrument or risk losing

their warranty (after all, their assumption is that they got the "latest"

technology in the field!). Thus, a whole generation of well intentioned workers

is trapped. This may explain why we often come across some

pompous paper titles hinting at thorough and deep-going scientific work, whilst

the authors cannot even untangle themselves from the artificial constraints of their

machines. None of these works has improved the commercial ESEM one iota,

even in full view of the latter being downgraded to low vacuum SEM.

Pompous titles yes, but real progress none. It now requires some

courageous individuals to get out of this trap, scientists should

start speaking out, at least some of those still operating the older models that

provide better outcomes. The rest of the truth must be sought elsewhere when we

examine events behind the academic

world .

Based on the evidence given above, one should appreciate

why there are several commercial ESEMs around that represent a serious

deviation from the goals and achievements originally obtained and

set. With any description of "how ESEM works" [also mirrored here ], it must be

made clear that the description applies to a particular commercial ESEM type and

not to ESEM in general. The instructions may well be based on

a retrogressive design: That is an example of the artificial

limitations imposed on working pressure range, beam kV, field of view, image

noise (hence dependence on image averaging), working distance, temperature

(hence dependence on cooling), charging of large insulating specimens,

etc. The ESEM, in general, is not like SEM with "two added degrees of

difficulty" but a particular commercial

brand may be so. It is ironic that the truth (fortunately) is exactly in the opposite

direction: ESEM has created new degrees of freedom and ease of operation!

A more general description of how ESEM works can be found here .

A proper ESEM is the one that allows the user to operate

at room temperature, under fully wet conditions, at low kV (less than 5 kV),

with sufficient space to allow most applications and ancillary devices

(like a microinjector), and a large field of view. These, in

turn, allow excellent contrast and resolution with minimum or no

specimen damage, all of which, in turn, allow an unlimited number of

applications. However, ill-conceived commercial instruments may only have

an opposite effect on the market, which, in turn, is used as internal company

argument against normal progress. The ESEM, in general, should not be

identified with any single form of commercial make. The term ESEM was

introduced prior and independently of the commercial developments and there

should be a clear distinction of terminology regarding the technology per se and

various commercial forms of ESEM.

It is very striking if one considers the achievements at the very

outset or ( 1 ) of this work, let alone the

breakthroughs that followed in the decade after that. When imaging could

be obtained at pressures in excess of 50 mbar (5000 Pa) in the

year 1978 with the simplest modifications to a 1968-make of an old SEM

and with meagre resources and a shoestring budget, whilst present day

"state of the art" machines are constrained to low vacuum and pressure with

crude operational parameters, the scientific community becomes seriously

concerned. This exposition clearly shows that beyond the general

understanding of the foundations and principles involved, success

also involves the art of adequate precision in the design and construction

of an ESEM. This clearly indicates that the engineering crudeness factor of various design parameters on commercial instruments is at least

one order of magnitude out of the scientifically prescribed one. Any

scientist or user of this technology must wonder why this is so. Three

broad causes can be proposed: (a) The commercial engineers have never

experienced the levels of achievement by the

ESEM Research Laboratory , (b)

they may have not read or have never understood the

published works , (c)

there are other obscure reasons outside scientific logic.

Clearly, an ESEM optimally designed to operate at high

pressure is automatically superior in performance at low pressure or low vacuum

without further ado: An optimal ESEM design is good both for low and high

pressure work. The internal argument used by manufacturing personnel that

"there is not high demand for high pressure work" is very poor indeed:

Firstly, it is absolutely false to claim that there is not high demand in the

market for high pressure work. Secondly, even if the previous claim were

to be correct in some way, you do not go about compromising and corrupting the

engineering design because allegedly there is no high demand in the high

pressure range. This is ludicrous and obscure thinking (yet

it happens!). How can you expect a demand for high pressure work if

the current offerings to an unaware market are ineffective? Furthermore,

you simply cannot expect the market forces alone to ensure optimum operation of

the ESEM product, since this is not an every day commodity like milk and

bread, or cars. The market forces to operate for this commodity

(ESEM) can have a time lag of 20-30 years and have no immediate

practical consequence. The first commercial ESEM did not come

about because customers were demanding it from the manufacturers. It was

the initiative of a small group of people who promoted it in the first place and

the market followed. After that, supply and demand go hand in hand but the

key is to maintain a healthy supply. A good product will increase

demand. Bad reputation will stifle the market. Hence the

manufacturers are obliged to live up to the expectations of this newly

created market, if progress is to made and if they are genuine in their

commitment to serve science and technology. In parallel, scientists must

press ahead with progress despite all odds.

Herewith, we have exposed several instances

of artificial technological mishaps, unnecessary and avoidable

throughout ESEM's commercial existence. We can also understand why an

ESEM should not simply be identified with the commercial detector of "GSED"

(a misnomer for the gaseous detection device) as is often inappropriately

done. For what is the use of the latter detector in an machine that

results in massive electron beam losses during transfer, or incurs frequent

contamination and image deterioration, or sustains only short electron gun life,

or desiccates and kills fresh specimens prior to achieving 100% relative

humidity, or blasts delicate specimens under forced high accelerating voltage

beam operation, or has to operate only with a cooling device mainly

at freezing conditions, or provides poor BSE imaging, or is cumbersome

to operate, or has long down times and requires frequent service

requests? ESEM is the synergy of a host of technological musts. In

short, we have demonstrated several clear cases for

improvements waiting for implementation for a long time

now. There is no technological justification of why these problems have

appeared at all. The explanation must be sought in the management of human

resources by the manufacturing world and in the tolerance or

misguidance demonstrated by the academic world . The historical reasons for the delay in

the implementation of what otherwise should have been plain and natural

ESEM development during the last 20 years constitutes a topic to be dealt with

separately, when we look behind

the commercial world.

All obstacles above have a solution and so scientists and

users of ESEM should not lose heart in their continued efforts to do the

best out of this unique technology even in the present form available

to them, whilst striving to steer the commercial ESEM in the right

direction. Manufacturers must realize that there is a technological

"vacuum" in the market which should be filled with a fully fledged ESEM in

accordance with proven specifications (e.g. optimum design

specifications ), which still remain beyond the reach of mainstream

users. Bygone previous patent limitations, the key now is the

"know-how" for ESEM excellence. It remains to be seen which

manufacturer will be the first to fill this vacuum...

Please note: If your experiences relate to any of the

problems outlined above, you may wish to send a comment to

esem@bigpond.com

.jpg)

.jpg)

.jpg)